Black EPDM Solid Extrusion Profile Rubber Strip Excellent Water

Resistance O Ring Cord

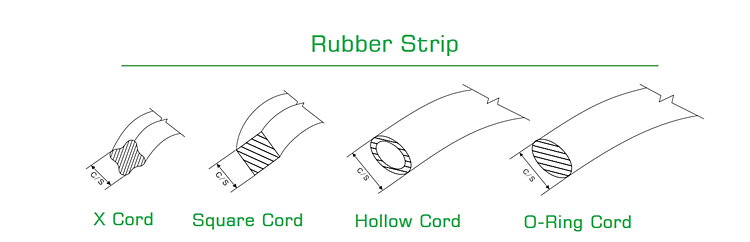

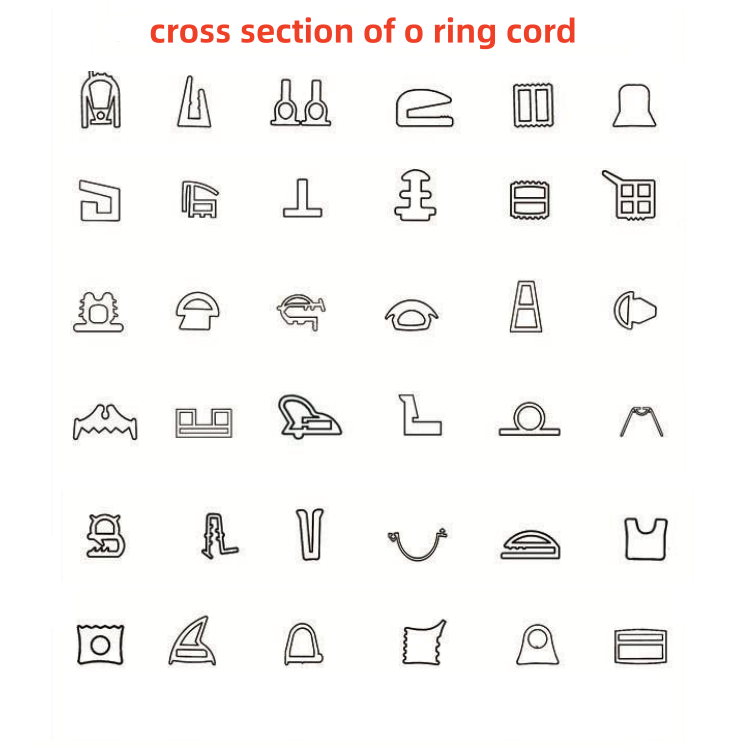

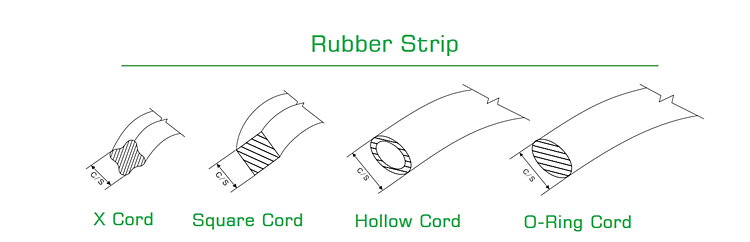

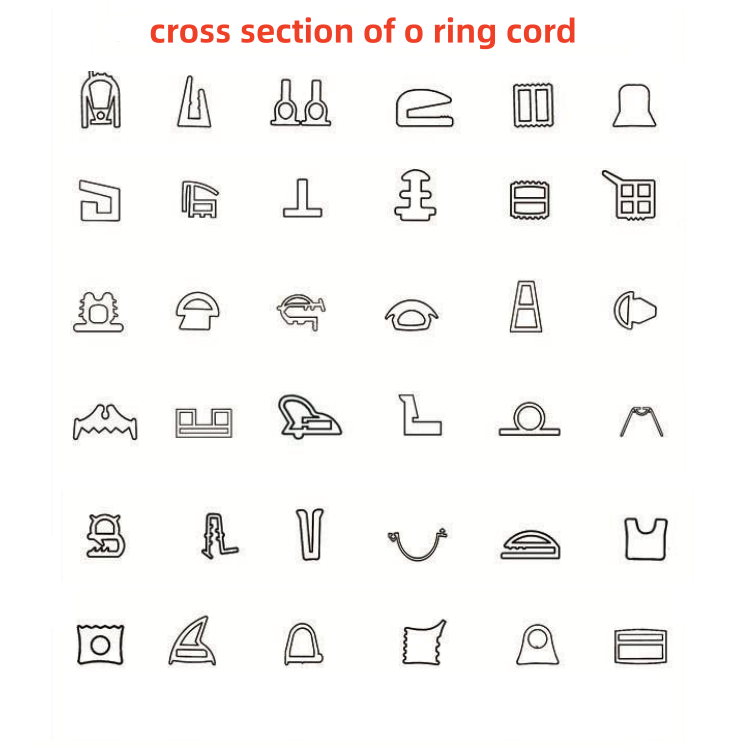

O Ring cord/ Rubber strip

Function of the rubber o ring cord

Rubber O-ring cords is a commonly used name for extruded sections

made of homogenous rubber.

We offer rubber cords in versions with round and square profiles.

The selection of the right profile

of the sealing cord depends on the application. Rubber sealing

cords are made by the extrusion and

free vulcanization of rubber mixtures.

Main Features

1) Climate resistance

2) High impact resistance and a low coeffient of friction

3) Corrosion resistance

4) High temperature resistance

5) Abrasion resistance

6) Environmental protection materials

EPDM Material Feature

| Material | EPDM(Ethylene propylene Rubber) |

| Advantage | 1,Excellent Weathering Resistance |

| 2,Excellent Ozone Resistance |

| 3,Excellent Flame Resistance |

| 4,Excellent Heat Resistance |

| 5,Excellent Water Resistance |

| 6,Excellent Oxygenated-Solvent Resistance |

| Disadvantage | 1,Poor Oxygenated-Solvent Resistance |

| 2,Poor Oil and Fuel Resistance |

| Temperature | -50℃-150℃, -50℃-200℃(Special formula) |

| Application | 1,Shower Sealings or parts |

| 1,Rubber parts for brake (brake) systems |

| 2,Radiator (Automotive tank) seal |

EPDM Rubber Features:

EPDM rubber is a high density rubber primarily used for outdoor

applications. It has dynamic

and mechanical properties between natural rubber and synthetic

rubber.

Do not use EPDM if continual contact with petroleum based products

is required.

Not recommended for usage in food applications or those that are

exposed to aromatic hydrocarbons.

O Ring cord/ Rubber strip applications:

1) The primary application for cords is as the basic material for

joined O-rings.

2) They are similar to the O-ring in the way they are handled and

applied.

3) They are used as static seals, e.g.

4) for sealing larger pipe unions and as cover seals in container

construction.

5) Cords are frequently used for on-site repairs, being joined

together to provide the "customized"

dimensions.

We supply NBR O Ring Cord , FKM O Ring Cord , Silicone O Ring Cord , EPDM O Ring Cord etc.Every material

has its advantages .You can choose as your requirements

Peculiarity Of O Ring Cord:

1) NBR O Ring Cord:Good chemical resistance to mineral oils and greases,hydraulic oils

H, HL, HLP,

non-inflammable hydraulic pressure fluids HFA, HFB, HFC to approx.

+50°C and water to max. +80°C.

2) FKM O Ring Cord: Good chemical resistance to mineral oils and greases, synthetic

oils and greases,

engine, transmission and ATF oils to approx. +150°C

3) EPDM O Ring Cord:

Good resistance to hot water and steam, detergents, caustic potash

solutions, silicone oil and greases,

many polar solvents, and many diluted acids and chemicals, along

with a high level of ozone resistance.

4) Silicone O Ring Cord

Good resistance to water (up to 100 °C), aliphatic engine and

transmission oils, animal and plant oils

and fats..

| Material | Temperature | Characteristics | Application |

| NR | -50~80℃ | Good elasticity, tensile strength, wear resistance | Tires, cushions, seals, cable insulation sleeves |

| NBR | -40~120℃ | Oil resistance, wear resistance, high temperature and aging

resistance | Oil resistant seals, diaphragms, hose and soft tubing |

| SIL/VMQ | -60~250℃ | High and low temperature resistance, non-toxic tasteless, aging

resistance, insulation resistance, good thermal conductivity | Household articles, seals, shock absorbers, electronic accessories |

| EPDM | -40~150℃ | Weather resistance, ozone aging resistance, steam resistance,

strong acid and alkali resistance | Phosphate hydraulic oil system seals, hose and auto parts |

| FKM/FKM | -40~240℃ | High temperature resistance, oil,chemical,aging resistance, good

insulation, flame-retardant, less

breathabilities | Heat and oil resistant sealing parts, rubber hoses |

| SBR | -50~110℃ | The property is close to NR. good wear

and aging resistance. heat resistance is better than NR, but short

service life | Tire, rubber sheet, rubber hose, rubber adhesive tape |

| HNBR | -40~150℃ | Not easy to wear and deform, oil resistance | Aerospace, automobile, oilfield drilling, petrochemical, textile

and printing |

| CR | -40~120℃ | Weather and ozone aging resistance, self extinguishing, good

tensile strength, elongation and elasticity, good adhesion

with metal and fabric | Sealing ring, rubber tube, coating, wire insulation layer, adhesive

tape and prepared adhesive |

| FVMQ | -40~177℃ -40~232℃( Dry environment) | Resistant to strong acid, high and low temperature, oil, high

pressure and aging | Mechanical seal, petroleum industry, chemical industry, building

materials |

| FFKM | 250℃(regular) 320-330℃ (formula) | Good performance, used in harsh environments, resistant to various

solvents, strong acid and alkali, and good elasticity | High quality and expensive seal rings. |

| PU | -40~90℃ | Not easy to wear, withstand high pressure, not easy to aging and

hydrolysis | Building, automobile, aviation industry, thermal insulation,

household goods, household appliances |

| PTFE/F4 | -80~260℃ | Resistant to corrosion and abrasion, high and low temperature,

aging, high pressure and all organic solvents | Exhaust, steam pipes for transporting corrosive gases,high-pressure

oil pipes,cold compression systems, valves and other chemical

equipment. |

| PVC | -40~85℃ | Light material, chemical resistance, low flow resistance, high

mechanical strength, and good electrical insulation | Water and gas supply and drainage, irrigation, exhaust pipes, wire

conduits, industrial anti-corrosion for

residential, industrial and mining. |

| PA | -20~150℃ | Excellent strength, abrasion and chemical resistance,moisture

absorption, long service life,

elasticity and easy cleaning. | Clothing, reinforcing materials of rubber materials (such as

tires), ropes, vehicles and mechanical

equipment. |

Our Factory

Rui Chen Sealing Co., Ltd was built in 2006, now there are more

than 200 staff. The company has two

branches in Guangdong and Jiangxi, They are Dongguan Rui Chen Sealing Co.,

Ltd. and Shangrao Rui

Chen Sealing Co., Ltd..In recent years, the company has been supported by ShangRao

municipal government

and fully enjoy all the preferential policies for economic development zone. We will always

take "best quality,

best service" as our mission, and make progress together with you, harmony and mutual

win!

Certificates

1,

IATF16949

2.ISO9001

3.ISO14000

Progress

FAQ

Q: 1 What kinds of materials can you provide?

A: NBR, EPDM, SILICONE,FKM(FKM),NEOPRENE(CR), HNBR ,NR, IIR, SBR,

ACM, AEM,Fluorosilicone(FVMQ),

FFKM etc.

Q: 2 How to select the raw compound for my application?

A: With years of experience working with a variety of material, we

can help select the material that will best suit your

needs while keeping material costs in mind.

Q: 3 How long can we get the quote?

A: If your information is complete, we will provide the quotation

within 8 hours.

Q: 4 Can you provide samples? Is it free or extra?

A: Yes, we can provide samples for free. Freight can be negotiated.

Q: 5 What is the normal lead time for product orders?

A: If the stock generally takes 3-7 days, mold about 15-18 days, no

mold about 25-30 days, depending on the product

situation.

Q: 6 How to check the quality of the bulk order?

A: We have incoming inspection, control the quality of raw

materials, process inspection,to ensure the quality of the

production process, shipping 100% of the full inspection; automatic

inspection machine full inspection, and according

to customer needs before the mass production of pre-production

samples.

Q: 7 What is your standard packing?

A: Plastic bag for inner packing .carton box for outer packing also

be packed according to customer's requirements.

Q: 8 What's the payment term?

A: We accept T/T 30% deposit and 70% balance against copy of B/L or

L/C at sight, Paypal is also accepted.