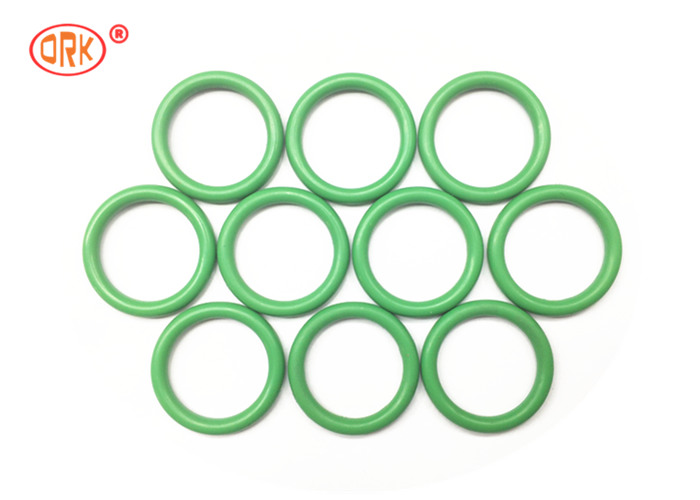

Colored Fuel Injector Pressure Washer O Rings Chemicals / Steam

Resistant

ASTM D1418 Designation: FKM

ORK Compound Designation: VT

Standard Color: Green, Brown Black

Description: Combining high temperature resistance with outstanding chemical

resistance, Fluorocarbon-based compounds approach the ideal for a

universal O-ring material.

Key Use(s): Seals for aircraft engines. Seals for automotive fuel handling

systems. High temperature/low compression set applications. Wide

chemical exposure situations. Hard vacuum service.

Temperature Range

Standard Compound: -13° to +446°F

Special Compound: -40° to +446°F

Hardness (Shore A): 55 to 90.

Features: High fluorine grades offer higher resistance to swell in high

octane and oxygenated fuel blends. This give superior performance

in Ethanol/Methanol blended gasoline. Base resistant grades offer

improved resistance to amine based oil protectants found in new

transmission oils. Also, improved resistant to steam for higher

temperature services. Low temperature bases can improve performance

to -40°F.

New Polymers being offered have improved chemical resistance and

low temperature performance.

FKM® Extreme™ ETP offers similar chemical compatibility as Kalrez™

with temperature performance with a TR(10) of -40°F and brittleness

to -76°.

Limitations: Fluorocarbons (FKM®s) are not recommended for exposure to ketones,

amines, low molecular weight esters and ethers, nitro hydrocarbons,

hot hydrofluoric or chlorosulfonic acids, or Skydrol® fluids. They

are also not recommended for situations requiring good low

temperature flexibility.

Material Description:

| MATERIALS TEST REPORT |

| FKM 70 GREEN COMPOUND |

| ASTM D2000 M2HK 707 A1-10 B38 EO78 EF31 F13 |

| Press Cure | Post Cure |

| Sheet : 10min 170℃ | Sheet : 16 hrs230℃ |

| Button : 10 min 170℃ | Button : 16 hrs 230℃ |

| ORIGINAL PROPERTIES | SPECIFICATION | TEST RESULT | ASTM TEST METHOD |

| HARDNESS SHORE A | 70°±5 | 71 | D2240 |

| TENSILE STRENGTH, MPA, MIN | ≥7 | 8.13 | D412 |

| ULTIMATE ELONGATION, %, MIN | ≥175 | 209.16 | D412 |

| SPECIFIC GRAVITY (g/cm3) | | 2.05 | D297 |

|

| HEAT RESISTANCE 70 H . AT 250℃(A1-10) | | | D573 |

| CHANGE IN HARDNESS, POINTS | +10 | +4 | |

| CHANGE IN TENSILES STRENGTH, % | -25 | +20.66 | |

| CHANGE IN ULTIMATE ELONGATION,MAX % | -25 | -7.49 | |

|

| COMPRESSION SET, MAX, 22H AT 200℃(B38 ) | ≤30 | 20.52 | D395 |

|

| FLUID RESISTANCE FUEL.101. 70H AT 200℃(EO78) | | | D471 |

| CHANGE IN HARDNESS, POINTS | -15~+5 | -9 | |

| CHANGE IN TENSILES STRENGTH, MAX % | -40 | -18.6 | |

| CHANGE IN ULTIMATE ELONGATION,MAX % | -20 | -12.6 | |

| CHANGE IN VOLUME % | 0~+15 | +9.85 | |

| | | |

| FLUID RESISTANCE FUEL C, 70H AT 23℃ (EF31) | | | D471 |

| CHANGE IN HARDNESS, POINTS | ±5 | -3 | |

| CHANGE IN TENSILES STRENGTH, MAX % | -25 | -15.2 | |

| CHANGE IN ULTIMATE ELONGATION,MAX % | -20 | -12.6 | |

| CHANGE IN VOLUME % | 0~+10 | +5.2 | |

|

| LOW-TEMPERATURE BRITTLENESS NONBRITTLE | | | |

| AFTER 3MIN AT -10°C (F13) | NONBRITTLE | PASS | D2137 |

Notes:

1. The data are based on testing slabs I buttons and are for

reference purpose only.

2. Our compound can meet above -mentioned ASTM 2000 Spec.

3. This information is, to the best of our knowledge, accurate

reliable to the date indicated.

4. The above mentioned data have been obtained by tests we consider

as reliable, We don't assure that

- the same results can be obtained other laboratories, using

different conditions by the preparation and evaluation of the

samples.